MONROE CABIN SHOCK ABSORBERS

MONROE CAB SHOCK ABSORBERS

For professional truck drivers, long journeys mean not only many kilometers covered, but also the constant need to manage body fatigue, muscle tension and chronic vibration stress. Continuous shaking felt inside the cab, high-frequency vibrations and impacts from the road surface are factors that, over time, distract the driver’s attention, cause chronic back and spine problems and, most importantly, endanger driving safety. Under these demanding working conditions, MONROE cab shock absorbers are no longer just a simple spare part; they become a vital component for the truck’s overall ergonomics, protecting the driver’s health, comfort and, indirectly, operational efficiency.

The correct performance of the cab suspension system is the key to maximizing cab comfort and absorbing engine vibrations. So when does this critical part fail, how can you recognize the failure, and why should you choose an established global brand like MONROE when replacing it? In this comprehensive article, we will examine in detail the engineering science behind cab comfort, MONROE cab shock absorber technology and the critical warning signs that you should never ignore regarding replacement time, and we will analyze the direct link between truck comfort and driving safety.

The Function of Cab Suspension and Why It Wears Out

Preventing the mechanical vibrations produced by the truck’s main chassis and powerful engine, the impact energy and the shocks caused by road surface irregularities from being transmitted to the cab is entirely the duty of the cab suspension system. Cab shock absorbers are the most important and hardest-working components of this system. These parts absorb most of the high-frequency vibrations generated by the engine and driveline and keep the cab’s movement over the chassis under control, scientifically reducing the stress placed on the driver’s body. The driver being rested, comfortable and highly focused is vitally important both for personal safety and for other vehicles in traffic. For this reason, in fleet cost calculations, cab shock absorber prices should be seen not as an expense, but as an investment in human health.

The Level of Comfort MONROE Technology Provides to the Driver

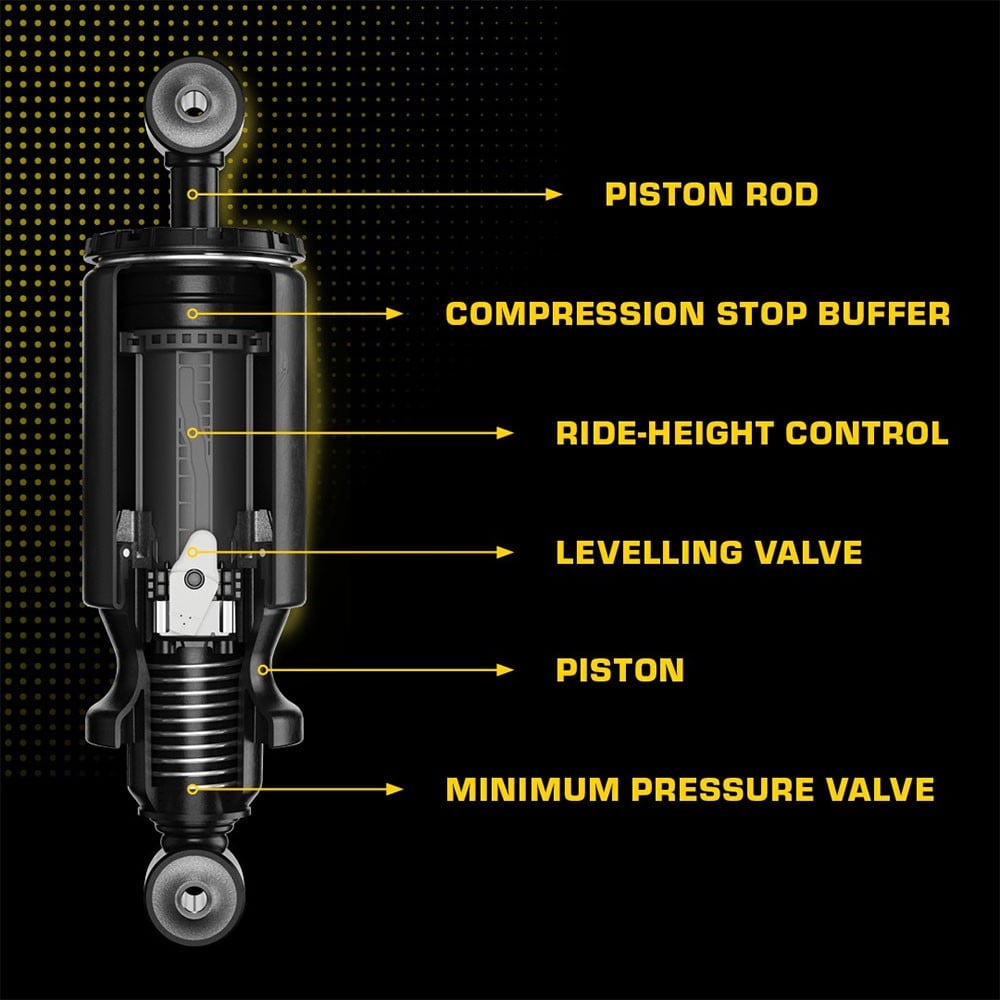

The MONROE brand, with more than a century of experience in suspension and shock absorber technologies, is one of the global leaders in this field. MONROE cab shock absorbers, which are specially designed for heavy commercial vehicles, do not only absorb vertical impacts; they also significantly increase stability by controlling excessive cab roll (especially when entering sharp bends or during sudden maneuvers). These parts are manufactured to the Original Equipment (OE) standards defined by vehicle manufacturers and are calibrated to match perfectly with the truck’s original suspension geometry. The precise valve systems used in the internal structure of MONROE shock absorbers and the specially formulated hydraulic fluids deliver optimum damping performance under different road conditions and temperature changes. This technological superiority means the driver becomes less fatigued and enjoys a comfortable driving experience even on long distances, just like at the beginning of the journey. Low-quality aftermarket products generally lose their damping capability in a short time, cause the cab to bounce uncontrollably and very quickly reduce the driving comfort of the truck to zero.

Replacement Time for MONROE Cab Shock Absorbers: Operational Safety Indicators

Cab shock absorbers, like the truck’s main suspension system, are unfortunately destined to wear out and lose performance over time. However, because the cab appears to sit in place from the outside, fault detection is often neglected. So, as a driver or fleet manager, what are the definite and critical signs that the time for cab shock absorber replacement has come? Ignoring these signs can lead to consequences as serious as an engine failure.

1. Noticeable Increase in Vibration and Abnormal Noises Inside the Cab

If the level of vibration felt inside the cab, especially at idle, at low speeds or at a certain engine speed, has clearly increased, this is the first and most important sign that the shock absorbers are no longer doing their job. It means that the shock absorbers are becoming insufficient at absorbing the high-frequency vibrations produced by the engine and chassis. This vibration not only reduces driver comfort, but also shortens the service life of cab plastic trim and electronic control units (ECUs). If the driver frequently complains of back pain, stiff neck or numbness in the hands while holding the steering wheel, checking the shock absorbers becomes mandatory.

2. Uncontrolled Excessive Bouncing and Swaying on the Road

The most obvious physical sign is uncontrolled bouncing of the cab when driving over road irregularities or during sudden braking. When the shock absorbers completely lose their damping capability, the cab “jumps” on its springs, flexing excessively, or continues to sway for a long time after passing over a speed bump. This is not only uncomfortable and tiring, but also dangerous. Especially in windy conditions and loaded cornering, uncontrolled cab movement can cause the driver to temporarily lose visibility and overall control of the vehicle. In such situations, it is urgent to start researching MONROE cab shock absorber prices and plan replacement.

3. Visible Leaks, Bushing Damage and Mounting Points

If there is visible oil or hydraulic fluid leakage on the shock absorber body, this means the damping function has effectively ended. A fluid leak indicates that the hydraulic oil inside the shock absorber has been lost and the component can no longer perform its function. In addition, if cracks, separation or excessive looseness are observed in the rubber bushings used at the mounting points of the shock absorbers, this leads to noisy operation and additional vibration. Such visual and physical damage are definite replacement signals that require the intervention of a specialist.

4. Mileage Threshold Exceeded

Most truck manufacturers and suspension experts strongly recommend preventive replacement of cab shock absorbers within a certain mileage interval (usually between 400,000 and 600,000 km, depending on the road conditions in which the vehicle operates). Even if there is no obvious fault in your parts yet, once such high mileage has been reached, the likelihood of reduced damping performance is high. Preventive replacement keeps driver comfort consistently high and prevents the shock absorber from failing unexpectedly at a critical moment on the road.

The Hidden Cost and Risk Analysis of Aftermarket Cab Shock Absorbers

When budget-focused, ucheap cab shock absorber prices are preferred and aftermarket products are chosen for cab shock absorbers, the initial savings can be misleading. This saving has the potential to turn into major operational and health-related costs in a short time.

Aftermarket shock absorbers are often manufactured with low-quality seals, simple valve systems and hydraulic fluids that oxidize quickly. This causes the shock absorber to lose its damping performance in as little as 50,000–100,000 km. Once the shock absorber becomes ineffective, the driver’s comfort and safety are compromised. More importantly, due to poor damping performance, high levels of vibration continue to be transferred to the cab structure, the entire dashboard, the steering system and the most sensitive components — the electronic control units (ECUs). This leads to premature wear at cab mounting points, frequent electronic failures and increasing physiotherapy or health expenses for the driver. Investing in a proven brand such as MONROE shock absorber is not only an investment in the shock absorber itself; it is a critical investment in the overall condition of the truck and, above all, in the long-term health of your most valuable asset — your driver. A quality component definitely reduces operating cost per kilometer in the long run and helps preserve the truck’s resale value.

Driver Comfort = Fleet Efficiency and Safety

Fleet managers and operators must recognize that driver comfort is not only a human requirement, but also a direct commercial advantage. Fatigue and loss of concentration caused by constant vibration statistically increase the risk of accidents. A driver working in a comfortable cab with minimized vibration makes fewer mistakes, stays focused for longer periods and is more engaged in the job. Using MONROE shock absorbers both demonstrates the value you place on the driver and significantly increases driver loyalty and morale. This is a critical competitive advantage, especially today when it is difficult to find qualified drivers.

The replacement of cab shock absorbers should occupy an important place in the truck’s overall maintenance schedule. During replacement, it is essential to use parts with original equipment quality to ensure the system continues to operate at high performance. After replacement, it should be observed that the cab has returned to its normal, controlled suspension movement and that road vibrations have been reduced to a minimum.

In conclusion, MONROE cab shock absorbers are not just a spare part, but an investment tool for ensuring the continuity of heavy-duty operations. This investment, in the long term, protects your driver’s health, increases fleet efficiency and reduces unexpected breakdown and accident risks. Ignoring even the slightest sign of weakness in your cab suspension means taking away from the overall life, comfort and driving quality of your truck.

For detailed technical information and supply regarding cab shock absorber solutions with MONROE assurance, suitable for the make and model of your truck, contact our suspension specialists immediately.